|

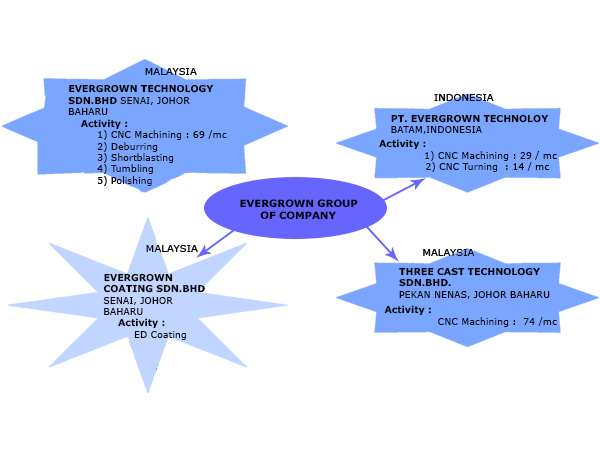

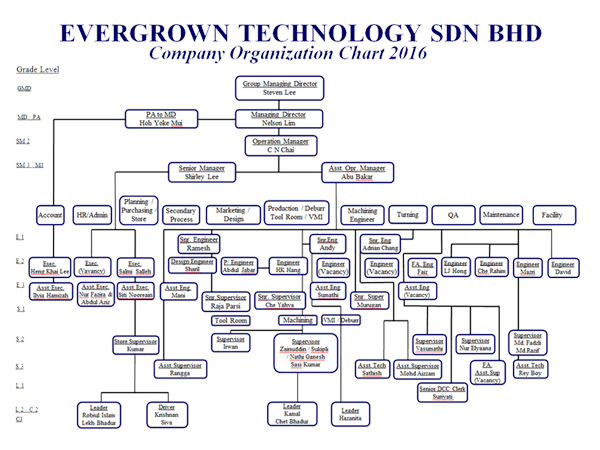

Precision Machining is our forte and to support our business focus and objectives, we have, over the years, planned, trained and retained human resources that contribute. Precision Machining is our forte and to support our business focus and objectives, we have, over the years, planned, trained and retained human resources that contribute.

We also continuously review and upgrade our skills, methods, processes, tools and equipments to exploit the most out of the best in advancing global technologies so as to deliver better products at competitive prices

As a testimony to our fervent commitment to high cutting-edge technology, below are some of the equipment and machinery we utilise:

Turning Department

Tooling Department

|

7 units

3 units

2 units

2 units

|

CNC Turning machines

CMM

Surface Grinding

Turning Manual Machines

|

|

|

|

Production Department

Total CNC Machine : 69units

Various Height Gauge, Micrometer, CAD & CAM Software system, Surface Roughness Reader, Elcometer (for Coating/Plating thickness ), RO system ( to produce DI water for washing line and others).

Manageable Material :

Copper ( including brass, bronze, beryllium copper )

Aluminium ( extruded, casting, forged )

Steel ( carbon steel, mild steel, free cutting steel, etc )

Stainless Steel ( SUS303, 304,316 )

Sintered parts ( powder Metallurgy )

Non-metal ( nylon, PVC, etc )

All in forms of flat bar, rod, hexagon, hollow pipe or moulded profile.

Progress is a journey; not a destination, and as part of this journey towards perfection, we set our goals high from inception and through the years, maintained the highest possible standards we naturally have come to expect of ourselves.

Part of this unending journey is the target to attain ISO quality certification by Q3 2006.

We believe that it is only by keeping abreast and ahead of our competitors that we can continue to lead and support our customers towards excellence and peerlessness.

|